Formwork plywood plays a crucial role in ensuring the durability of concrete structures. By providing support and shape during the pouring and curing process, formwork plywood helps to create strong and long-lasting concrete components. In this article, we will delve into the basics of formwork plywood, explore its composition and role in construction, discuss its impact on concrete strength and lifespan, highlight the benefits of using formwork plywood in concrete structures, provide guidance on choosing the right formwork plywood for your projects, and take a glimpse into the future of formwork plywood in concrete construction.

Understanding the Basics of Formwork Plywood

Formwork plywood (Formply) is a type of plywood specifically designed for use in concrete construction. Formply Australia is typically made from high-quality hardwood veneers that are bonded together with a strong adhesive. The plywood panels are usually lightweight yet durable, allowing for easy handling and assembly on construction sites.

One of the key characteristics of formwork plywood is its smooth surface. This smoothness ensures that the concrete adheres well to the plywood, resulting in a high-quality finish. Additionally, formwork plywood can withstand the pressure exerted by the concrete during the pouring process, providing stability and preventing deformations. Learn more about top 7 safety tips to avoid scaffolding accidents.

The Composition of Formwork Plywood

Formwork plywood is typically composed of multiple layers of wood veneers. These veneers are carefully selected and arranged to create a strong and balanced plywood panel. Each veneer layer is oriented in alternating directions, which enhances the panel’s structural integrity and resistance to warping or splitting.

In addition to the wood veneers, formwork plywood may be treated with preservatives to protect against moisture and fungal decay. This treatment ensures that the plywood can withstand the harsh conditions encountered during concrete construction, including exposure to water and wet concrete.

The Role of Formwork Plywood in Construction

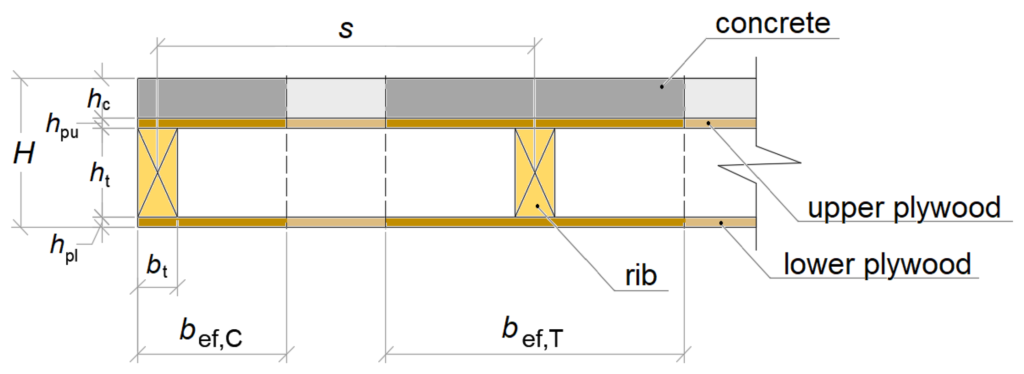

Formwork plywood serves as the mold or framework that shapes the concrete during the pouring and curing process. It is used to create the desired form and dimensions of the concrete components, including walls, slabs, beams, and columns. Without formwork plywood, it would be challenging to achieve precise and consistent shapes in concrete construction.

In addition to its shaping role, formwork plywood provides crucial support to the freshly poured concrete. It helps distribute the weight of the concrete evenly, preventing any sagging or deformation. This support allows the concrete to cure properly, ensuring its strength and durability over time.

Furthermore, formwork plywood is designed to be reusable, making it a cost-effective choice for construction projects. After the concrete has cured and the formwork is no longer needed, the plywood can be dismantled and used again for future projects. This reusability not only reduces waste but also saves time and resources in the long run.

Another advantage of formwork plywood is its versatility. It can be easily cut and shaped to fit various project requirements, allowing for flexibility in design. Whether it’s a complex architectural structure or a simple foundation, formwork plywood can be customized to meet the specific needs of the construction project.

Moreover, formwork plywood is known for its excellent dimensional stability. This means that it maintains its shape and size even when exposed to changes in temperature and humidity. This stability is essential in concrete construction, as it ensures that the formwork remains intact and the concrete retains its desired shape throughout the curing process.

In conclusion, formwork plywood plays a crucial role in concrete construction. Its smooth surface, composition, and support capabilities make it an ideal choice for shaping and supporting concrete structures. With its reusability, versatility, and dimensional stability, formwork plywood offers numerous benefits that contribute to efficient and successful construction projects.

The Relationship Between Formwork Plywood and Concrete Durability

Formwork plywood directly influences the durability of concrete structures through its impact on concrete strength and lifespan. By understanding the interplay between formwork plywood and concrete, engineers and builders can make informed decisions to enhance the durability of their projects.

How Formwork Plywood Affects Concrete Strength

The quality of formwork plywood has a direct impact on the strength of the concrete. High-quality plywood provides a smooth and even surface for the concrete to adhere to, resulting in a stronger bond between the two materials. This strong bond increases the load-bearing capacity of the concrete, making it less prone to cracking or failure under stress.

In addition to the bond strength, the thickness of the formwork plywood also plays a crucial role in determining the concrete’s strength. Thicker plywood can withstand higher pressure during the pouring process, allowing for the creation of concrete structures with greater structural integrity. This is particularly important in projects that require heavy loads or are exposed to harsh environmental conditions.

The Impact of Formwork Plywood on Concrete Lifespan

The use of formwork plywood can significantly extend the lifespan of concrete structures. By providing precise shaping and support, formwork plywood minimizes the risk of structural defects and long-term degradation. Well-designed and properly installed formwork plywood ensures that the concrete remains in its intended shape, preventing the formation of cracks or uneven settlements that can compromise the structure’s integrity over time.

Furthermore, the choice of formwork plywood material can also impact the concrete’s resistance to external factors such as moisture and temperature changes. Some types of plywood are specifically engineered to be highly resistant to moisture, reducing the risk of water damage and deterioration of the concrete. This is particularly important in projects located in humid or coastal areas, where exposure to moisture is a constant concern.

In addition to moisture resistance, the thermal properties of the formwork plywood can also influence the lifespan of the concrete. Plywood with good thermal insulation properties can help regulate the temperature during the curing process, ensuring that the concrete cures evenly and avoids the formation of thermal cracks. This is especially crucial in regions with extreme temperature variations, as it helps maintain the long-term durability of the concrete structure.

The Benefits of Using Formwork Plywood in Concrete Structures

There are several key benefits to using formwork plywood in concrete structures. These benefits include cost-effectiveness, environmental advantages, improved construction efficiency, and enhanced structural performance.

Cost-Effectiveness of Formwork Plywood

Formwork plywood offers significant cost savings compared to other formwork materials such as steel or aluminum. Plywood is generally more affordable and readily available, making it a cost-effective choice for projects of various scales. Additionally, formwork plywood can be reused multiple times, further reducing material costs and waste.

The lightweight nature of formwork plywood also contributes to cost savings. It is easier and quicker to handle, transport, and assemble than heavier alternatives. This efficiency translates into reduced labor costs and faster construction timelines.

Furthermore, the durability of formwork plywood ensures that it can withstand the rigors of construction, reducing the need for frequent replacements and maintenance. This longevity adds to its cost-effectiveness, making it a wise investment for concrete structures.

Environmental Advantages of Formwork Plywood

Formwork plywood is a sustainable choice for concrete construction. The wood used in plywood production is a renewable resource, and responsible forestry practices ensure its availability for future generations. Additionally, using plywood reduces the demand for non-renewable materials, such as steel or aluminum, which have a higher carbon footprint.

Moreover, formwork plywood can be recycled or repurposed at the end of its life cycle, minimizing waste and environmental impact. Proper disposal or recycling of used formwork plywood contributes to sustainable construction practices and reduces landfill burden.

Furthermore, the use of formwork plywood in concrete structures can help improve the energy efficiency of buildings. Plywood has excellent insulation properties, reducing heat transfer and improving thermal performance. This can lead to lower energy consumption for heating and cooling, resulting in reduced carbon emissions and long-term cost savings.

Enhanced Structural Performance

In addition to its cost-effectiveness and environmental advantages, formwork plywood also contributes to enhanced structural performance in concrete structures. The smooth and consistent surface of plywood helps achieve high-quality finishes, ensuring a visually appealing result.

Furthermore, formwork plywood provides excellent dimensional stability, minimizing the risk of warping or distortion during the concrete pouring process. This stability ensures accurate and precise formwork, resulting in structurally sound and aesthetically pleasing concrete structures.

Moreover, the flexibility of formwork plywood allows for the creation of complex shapes and designs, enabling architects and engineers to unleash their creativity and achieve unique architectural features. This versatility adds value to concrete structures, making them stand out and leaving a lasting impression.

Choosing the Right Formwork Plywood for Your Concrete Structures

Selecting the appropriate formwork plywood is essential to ensure the success of your concrete construction projects. Consider the following factors when choosing formwork plywood:

Factors to Consider When Selecting Formwork Plywood

- Strength and durability: Look for plywood that can withstand the pressure exerted by fresh concrete without deforming or delaminating.

- Moisture resistance: Choose plywood treated with preservatives to protect against moisture and ensure long-term durability.

- Smooth surface: Opt for plywood panels with a smooth surface to achieve a high-quality concrete finish.

- Reusability: Consider plywood that can be reused multiple times to enhance cost-effectiveness and reduce waste.

Tips for Proper Installation of Formwork Plywood

- Ensure proper alignment and bracing of plywood panels to maintain the desired shape and prevent bulging or leakage.

- Apply form release agents or suitable coatings to prevent the concrete from sticking to the plywood surface.

- Regularly inspect the plywood for signs of damage, such as cracks or delamination, and repair or replace as necessary.

- Store and handle the plywood carefully to prevent moisture absorption, warping, or other forms of damage.

The Future of Formwork Plywood in Concrete Construction

The use of formwork plywood in concrete construction is expected to continue evolving with advancements in technology and changes in industry practices. Here are some potential trends and technological advancements to watch out for:

Technological Advancements in Formwork Plywood Production

Manufacturers are continually improving the production processes and characteristics of formwork plywood. This includes the development of innovative bonding technologies, enhanced surface treatments, and improved moisture resistance. These advancements aim to further enhance the performance and durability of formwork plywood, making it an even more reliable choice for concrete construction.

Trends in Formwork Plywood Usage in Modern Construction

As sustainable construction practices gain momentum, the demand for eco-friendly formwork plywood is likely to increase. This may involve the use of certified sustainably sourced wood or the development of alternative materials with similar properties to plywood. Additionally, digitalization and automation in construction processes may lead to the integration of smart formwork systems that enhance efficiency and reduce labor requirements.

In conclusion, formwork plywood plays a vital role in enhancing the durability of concrete structures. Its composition, installation techniques, and quality directly impact the strength and lifespan of concrete. By choosing the right formwork plywood and following proper installation practices, builders can ensure the long-term integrity and performance of their concrete projects. As technology advances and sustainability becomes more crucial in construction, the future of formwork plywood holds exciting possibilities for further enhancing concrete durability and construction efficiency.