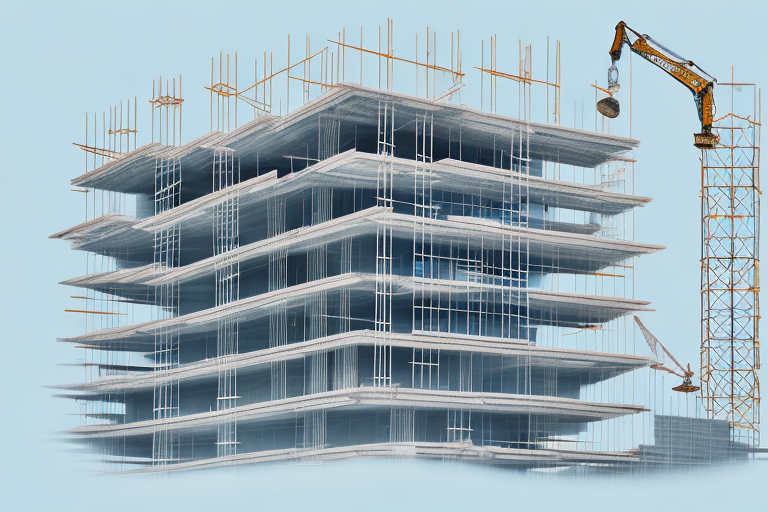

In the world of construction, finding cost-effective solutions is key to staying competitive in the industry. One material that has proven to be both economical and versatile is formwork plywood. Understanding its uses, benefits, and future trends can help construction professionals make informed decisions and maximize their project’s efficiency. This article will delve into the various aspects of formwork plywood and its role in construction.

Understanding Formwork Plywood

Definition and Uses of Formwork Plywood

Formwork plywood (Formply) is a specially designed wood panel that is used to create temporary molds, or formwork, for concrete structures. This type of formply is commonly used in construction projects where a smooth, level surface is required, such as walls, slabs, and columns. Buy formply and its use in structures provide a sturdy and consistent framework for pouring concrete, ensuring the desired shape and strength of the finished structure.

Formwork plywood is an essential component in the construction industry, playing a crucial role in shaping and supporting concrete structures during the building process. Its versatility and durability make it a preferred choice for contractors and builders looking to achieve high-quality results efficiently.

Key Features of Formwork Plywood

Formwork plywood possesses several key features that make it an ideal choice for construction projects:

- Durability: Formwork plywood is engineered to withstand the pressure and weight of fresh concrete, making it a reliable choice for demanding construction applications.

- Flexibility: It can be easily cut and shaped to fit different project requirements, allowing for customization and versatility.

- Reusability: Unlike traditional formwork materials like steel or plastic, formwork plywood can be reused multiple times, reducing waste and overall costs.

- Cost-Effectiveness: Formwork plywood offers a cost-effective solution compared to other materials, providing value without compromising on quality.

The durability of formwork plywood is a result of its construction using high-quality wood veneers and adhesives, ensuring it can withstand the pressure exerted by the concrete without warping or bending. This reliability is essential in construction projects where precision and structural integrity are paramount. Click here to unlock opportunities with a buyers agency.

The Economics of Using Formwork Plywood

Formwork plywood is a popular choice in the construction industry due to its cost-effectiveness and versatility. When evaluating formwork options, it is crucial to consider the cost implications associated with different materials. In many cases, formwork plywood emerges as the more affordable option when compared to materials like steel or aluminum. While the initial cost of formwork plywood may be slightly higher than some alternatives, its reusability significantly reduces the need for frequent replacement, resulting in lower overall expenses over time.

Cost Comparison: Formwork Plywood vs Other Materials

Formwork plywood stands out as a cost-effective solution for construction projects. Unlike steel or aluminum, formwork plywood offers a balance between affordability and performance. While steel and aluminum may have lower initial costs, the long-term financial benefits of formwork plywood often outweigh the upfront savings. Additionally, the versatility of formwork plywood allows for intricate designs and shapes to be easily achieved, further adding to its value proposition.

Long-Term Financial Benefits of Formwork Plywood

Aside from the immediate cost savings, formwork plywood provides substantial long-term financial advantages. Its durability and reusability enable contractors to complete multiple project cycles without incurring significant additional expenses. This not only translates to monetary savings but also contributes to sustainability efforts by reducing the environmental impact associated with disposing of traditional formwork materials. By choosing formwork plywood, construction companies can enhance their bottom line while promoting eco-friendly practices.

Implementing Formwork Plywood in Construction

Choosing the Right Formwork Plywood

Understanding the specifications and requirements of a construction project is crucial when selecting the appropriate formwork plywood. Factors such as load-bearing capacity, surface finish, and exposure conditions need to be considered. Consulting with industry experts and suppliers can help ensure the right choice for the job, balancing functionality and cost-effectiveness.

When it comes to load-bearing capacity, it’s important to assess the weight that the formwork plywood will need to support during the concrete pouring process. Different projects may require varying levels of strength, so choosing plywood with the appropriate structural integrity is key to ensuring the safety and stability of the construction site. Moreover, considering the surface finish is essential for achieving the desired aesthetic appeal of the concrete structure. Smooth formwork plywood can result in a polished surface, while textured plywood can create a more rugged appearance.

Best Practices for Using Formwork Plywood

To optimize the use of formwork plywood and maintain a high level of productivity, following best practices is essential:

- Regular Inspection: Regularly inspecting the formwork plywood for any signs of wear or damage can help prevent potential issues during construction.

- Proper Handling: Correctly handling and storing the plywood can extend its lifespan and maintain its structural integrity.

- Correct Formwork Installation: Ensuring precise and secure formwork installation is vital for achieving the desired concrete shape and finish.

- Attention to Concrete Pouring: Proper concrete pouring techniques, such as avoiding excessive vibration, can prevent unnecessary stress on the formwork plywood.

- Timely Removal: Following the recommended curing period, timely removal of the formwork plywood can optimize project timelines and minimize the risk of damage.

Additionally, incorporating safety measures during the use of formwork plywood is crucial to protect workers and maintain a secure working environment. Providing adequate training on handling and assembling the plywood can reduce the risk of accidents on the construction site. Implementing proper bracing and support systems can also enhance the stability of the formwork structure, ensuring the safety of workers and the integrity of the concrete form.

Sustainability and Formwork Plywood

Environmental Impact of Formwork Plywood

As the construction industry continues to prioritize sustainability, formwork plywood can contribute to eco-friendly practices. Its wood-based composition makes it a renewable and biodegradable resource, reducing carbon emissions compared to non-renewable alternatives. However, it’s crucial to source formwork plywood from responsibly managed forests and adhere to certification standards to ensure sustainable practices throughout the supply chain.

Moreover, the use of formwork plywood in construction projects not only aids in reducing carbon footprint but also promotes a circular economy. After serving its purpose in construction, formwork plywood can be repurposed or recycled into other wood products, extending its lifecycle and minimizing waste generation. This sustainable approach aligns with the principles of a circular economy, where resources are kept in use for as long as possible through recycling and repurposing.

Formwork Plywood and Green Building Standards

Formwork plywood aligns with various green building standards, such as Leadership in Energy and Environmental Design (LEED), which encourages sustainable construction practices. Using formwork plywood can contribute to LEED points in categories like Materials and Resources and Indoor Environmental Quality, further establishing its role as a cost-effective and sustainable construction solution.

Furthermore, the versatility of formwork plywood allows for efficient and precise construction, reducing material wastage and promoting energy efficiency during the building process. Its smooth surface finish also enhances the quality of concrete structures, resulting in durable and aesthetically pleasing buildings that meet high-performance standards. By integrating formwork plywood into construction projects, builders can achieve both sustainability goals and superior structural outcomes, demonstrating the significant impact of eco-conscious choices in the built environment.

Future Trends in Formwork Plywood Use

Technological Advances and Formwork Plywood

The construction industry is continually evolving, and advancements in technology are revolutionizing the way projects are executed. Formwork plywood is no exception. With the integration of digital tools like Building Information Modeling (BIM) and computer-aided design (CAD), construction professionals can optimize the use of formwork plywood, improving accuracy, efficiency, and cost-effectiveness.

One of the key technological advances in formwork plywood is the development of smart formwork systems. These systems incorporate sensors and actuators that enable real-time monitoring and adjustment of formwork conditions. By collecting data on factors such as temperature, humidity, and pressure, these smart systems can automatically make adjustments to ensure optimal performance. This not only enhances the durability and lifespan of the formwork plywood but also reduces the risk of errors and delays during construction.

Market Predictions for Formwork Plywood

The global demand for formwork plywood is projected to rise in the coming years, driven by factors such as urbanization, infrastructure development, and increasing focus on sustainable construction practices. As construction professionals recognize the economic and environmental benefits of using formwork plywood, its popularity is expected to grow, enabling more cost-effective and sustainable solutions in the industry.

Furthermore, the market for formwork plywood is witnessing a shift towards eco-friendly alternatives. Manufacturers are exploring innovative materials such as bamboo plywood, which offers similar strength and durability while being more sustainable and renewable. This trend aligns with the industry’s growing emphasis on sustainable construction practices and provides construction professionals with a wider range of options to choose from.

In conclusion, formwork plywood offers cost-effective solutions for construction projects. Its durability, reusability, and versatility make it an attractive choice for contractors aiming to optimize efficiency and reduce costs. As the construction industry continues to prioritize sustainability, formwork plywood’s environmentally friendly attributes further enhance its appeal. By staying informed about the latest trends and adhering to best practices, construction professionals can harness the benefits of formwork plywood and unlock its full potential in the ever-evolving world of construction.